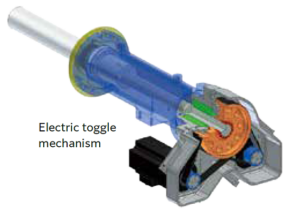

In order to realize the “New 3S” with high-productivity and low environmental impact die-casting machines, we have developed the R series die-casting machines,the world’s first die-casting machines equipped with an electric clamping mechanism as standard equipment.

This time, the R series has been further evolved and minor-changed to the R2 series.

Based on the “New 3S” concept, the R2 series features many improvements that

combine high productivity with reduced environmental impact, including improved workability.

The R2 series offers 250ton, 400ton, 500ton, 650ton, and 850ton die locking force lineups.

model | 射出構成 | 型締構成 | 制御装置 | ポイント |

|---|---|---|---|---|

DC*R2-EH | High grade servo injection | Electric die locking | TOSCAST-999 | Ultra-high performance (difficult casting, Mg) +Energy saving |

DC*R2-H | High grade servo injection | hydraulic die locking | TOSCAST-999 | Ultra-high performance (difficult casting, Mg) |

Distance between Tie-bars (V × H) | Standard grade servo injection | Electric die locking | TOSCAST-999 | Ultra-high performance (difficult casting)+Energy saving |

Die height | Standard grade servo injection | hydraulic die locking | OSCAST-999 | Ultra-high performance (difficult casting) |

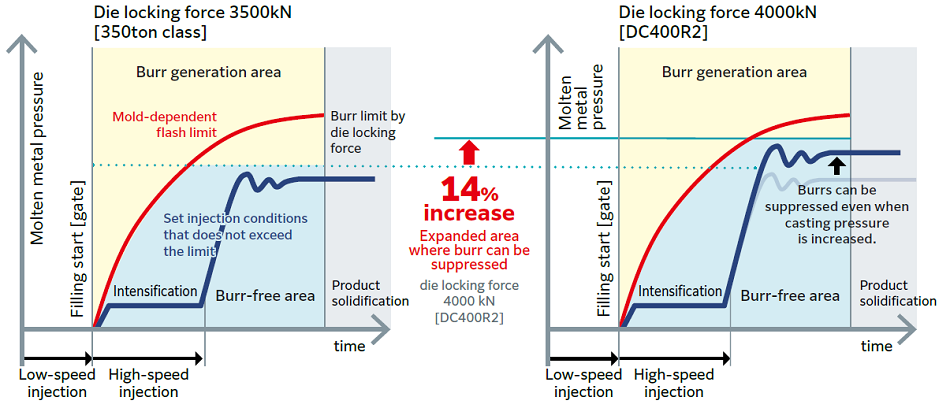

The conventional DC350R/DC800R series has been upgraded to DC400R2/DC850R2 in terms of die locking force clamping force.

DC350R is now 400R2 with 14% higher die locking force.

DC800R is now DC850R2 with 6% higher die locking force.

The die mounting relationship between DC350R and DC400R2 is the same.

Existing molds can take advantage of difference in die locking force.

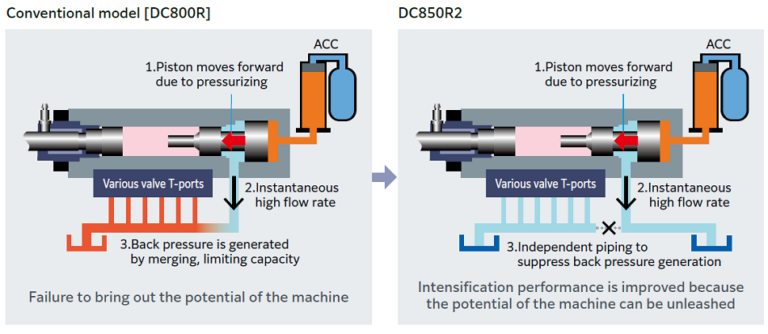

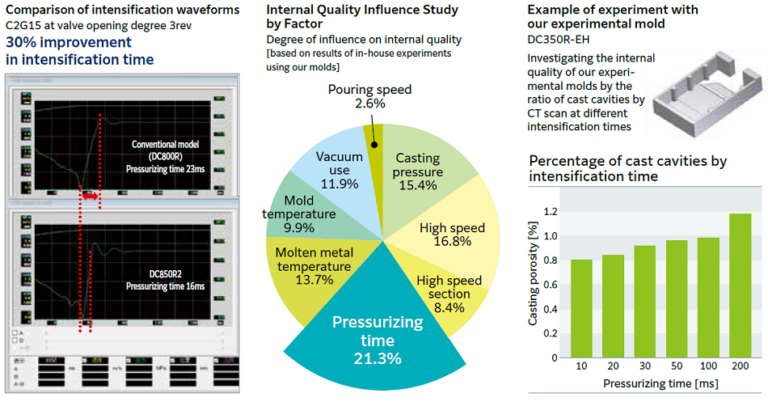

The injection piston is made lighter and more controllable by using a two-cylinder system: a speed cylinder for speed control and an intensification cylinder for intensification control.

Injection Structure Features

Reduces pressurizing time up to 9.6 msec with new intensification start control.

Speed control is added to the conventional position start control, and the pressurizing start timing changes according to the change in molten metal supply. The quality is stable even when used at high speeds or deceleration.

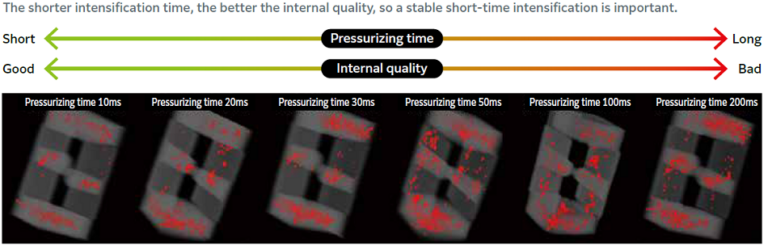

The shorter intensification time, the better the internal quality, so a stable short-time intensification is important.

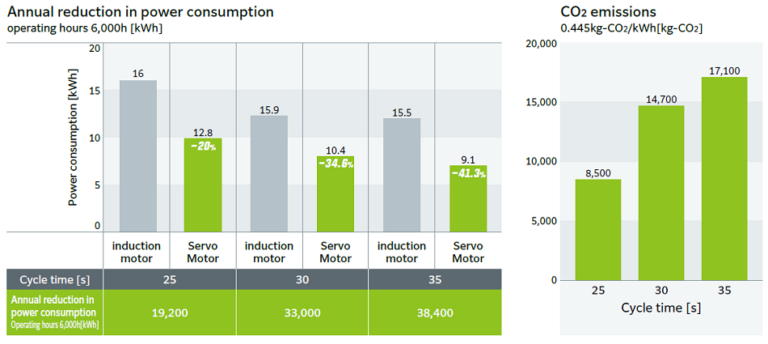

Servo-hydraulic source reduces power consumption by up to 41.3% compared to conventional hydraulic sources (for R2-E 400ton).

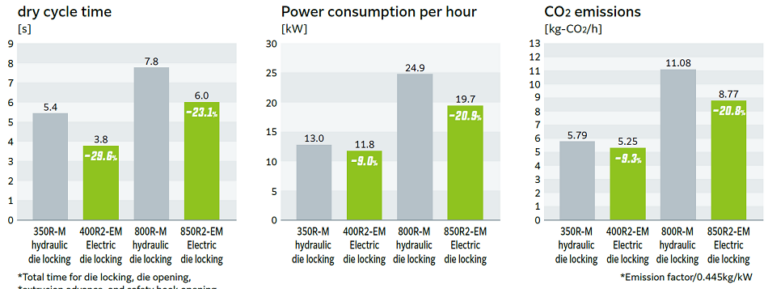

Electric toggle machines reduce CO2 emissions by up to 20.8% compared to hydraulic toggle machines.

DC850R2-EM compared to DC800R-M

Comparison of electric and hydraulic toggle machines

●CO2 emissions are expected 9.3% lower for DC400R2-EM than for DC350R-M

●CO2 emissions are expected 20.8% lower for DC850R2-EM than for DC800R-M

TOSCAST-999 is a controller for large size die casting machines (R2 series).

Improved operator visibility and operability with larger screen.

For more details, please refer to the above link.

dPAQET/dPAQET2 is software specialized for data collection from die casting machines.

It can be installed and used on ordinary computers, and it enables quick and inexpensive centralized management of information at foundry sites using LAN.

For more details, please refer to the above link.